Table of contents:

How Customization Enhances Sling Socket Performance

The Role of Babbitt Alloy in Tailored Sling Socket Solutions

Benefits of Investing in Wholesale Sling Sockets for Custom Projects

Designing Sling Sockets for Diverse Lifting Applications

How Customization Enhances Sling Socket Performance

Customization in sling sockets is a game-changer for industries requiring specialized lifting solutions. By working closely with a sling socket manufacturer, clients can specify requirements that align with their unique operational demands. Custom sockets allow for modifications in design, size, and material composition, ensuring optimal compatibility with specific rigging systems. This tailored approach not only enhances the performance of the sling sockets but also increases the safety and efficiency of lifting operations. For example, a customized socket can be designed to better align with hooks and shackles, providing greater stability and reducing the risk of structural failures. The ability to adapt sockets to various environmental conditions and load types is crucial for projects involving dynamic or high-frequency lifting, making customization a valuable investment for any industry.

The Role of Babbitt Alloy in Tailored Sling Socket Solutions

Babbitt alloy plays a pivotal role in the construction of high-quality sling sockets. Known for its excellent anti-friction properties and durability, Babbitt alloy ensures a secure and permanent bond between the wire rope and the socket body. This material choice is particularly effective for static or semi-static loads, such as those found in suspension cables and hoisting towers. A sling socket manufacturer utilizing Babbitt alloy can offer products that withstand extreme temperatures and environmental conditions, ranging from -40°C to 200°C. Additionally, the closed design of these sockets provides superior sealing against corrosion, making them ideal for marine and industrial environments. The use of Babbitt alloy not only enhances the longevity and reliability of sling sockets but also reduces maintenance needs, contributing to cost savings and operational efficiency.

Benefits of Investing in Wholesale Sling Sockets for Custom Projects

For businesses embarking on large-scale projects, investing in wholesale sling sockets from a reputable sling socket supplier can offer significant advantages. Purchasing in bulk allows for cost savings, as manufacturers often provide discounts for larger orders. This approach also ensures a consistent supply of high-quality sockets, tailored to meet specific project requirements. Working with a sling socket manufacturer who offers wholesale options enables companies to maintain stringent quality control across all their equipment, ensuring each socket performs reliably under demanding conditions. Furthermore, wholesale purchasing can facilitate faster project timelines, as it reduces the lead time associated with ordering individual units. By investing in wholesale sling sockets, businesses can streamline their operations, enhance project efficiency, and achieve greater overall success.

Designing Sling Sockets for Diverse Lifting Applications

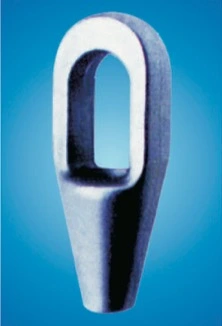

The versatility of sling sockets lies in their ability to be designed for a wide range of lifting applications. A skilled sling socket manufacturer can create sockets that cater to specific industry needs, whether it's for construction, marine, or industrial use. The closed-type design of these sockets ensures easy alignment with rigging systems, enhancing stability and safety. Moreover, the availability of various surface finishes, such as black and galvanized, allows for customization based on aesthetic and functional preferences. Sling sockets can be engineered to handle different load types, including static, semi-static, and dynamic loads, ensuring that they perform effectively across diverse scenarios. This adaptability is crucial for industries where lifting requirements may vary significantly, and having the right sling socket can make all the difference in achieving project success.

In summary, the importance of choosing the right sling socket manufacturer and supplier cannot be overstated when it comes to optimizing lifting solutions. Customization, the use of durable materials like Babbitt alloy, and the option to purchase wholesale are all key factors that contribute to the performance and reliability of sling sockets. By investing in tailored solutions, businesses can ensure their lifting operations are safe, efficient, and cost-effective. Whether for suspension bridges, oil rigs, or roof construction, the right sling sockets can enhance structural integrity and operational success, making them an indispensable component in the world of heavy-duty lifting and rigging.

No comments:

Post a Comment