Table of contents:

Exploring the Diverse Applications of Babbitt Alloy Sling Sockets

Custom Lifting Solutions: Adapting Sling Sockets for Various Industries

The Role of Wholesale Sling Sockets in Expanding Rigging Capabilities

How Babbitt Sling Sockets Support Versatile Lifting Solutions

Exploring the Diverse Applications of Babbitt Alloy Sling Sockets

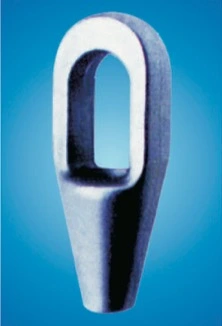

Babbitt alloy sling sockets are renowned for their versatility and robustness. These sockets are particularly effective in applications requiring permanent wire rope terminations. Their closed-type design ensures a permanent bond between the wire rope and the socket body, making them ideal for static or semi-static loads. This feature is crucial for projects involving suspension cables and hoisting towers, where structural reliability is paramount. The sockets are also designed for easy alignment with hooks and shackles, enhancing stability in rigging systems. As a prominent sling socket supplier, Jiangsu Gostern Rigging provides products that cater to a wide range of industries, ensuring that their clients receive solutions tailored to their specific needs.

Custom Lifting Solutions: Adapting Sling Sockets for Various Industries

The adaptability of sling sockets makes them suitable for a multitude of industries, from construction to marine environments. Jiangsu Gostern Rigging, a leading sling socket manufacturer, emphasizes the importance of custom lifting solutions to meet the unique demands of different sectors. Their products are manufactured through a precise casting process, available in various surface finishes, including black and galvanized. This flexibility allows the sockets to be used in diverse settings, such as roof construction and oil rigs, where they provide reliable and maintenance-free operation. By offering technical support and innovative solutions, Jiangsu Gostern Rigging ensures that their clients can optimize their rigging systems for maximum efficiency and safety.

The Role of Wholesale Sling Sockets in Expanding Rigging Capabilities

Wholesale sling sockets play a crucial role in expanding the capabilities of rigging systems worldwide. As a trusted sling socket supplier, Jiangsu Gostern Rigging offers a wide range of products that cater to both standard and custom requirements. Their sockets are designed to meet specific standards for wire ropes, ensuring compatibility and reliability in various applications. The closed design of these sockets provides superior sealing against corrosion, making them ideal for use in harsh environments. By maintaining stringent quality control and holding certifications like ISO9001:2015, Jiangsu Gostern Rigging continues to lead the industry as a top sling socket manufacturer, delivering products that enhance the efficiency and safety of lifting operations.

How Babbitt Sling Sockets Support Versatile Lifting Solutions

Babbitt sling sockets are integral to providing versatile lifting solutions across multiple industries. Their high strength and corrosion resistance make them suitable for high-frequency lifting and dynamic load applications. The closed-end construction of these sockets allows for easy alignment with rigging components, ensuring stability and safety during operations. Jiangsu Gostern Rigging, a renowned sling socket manufacturer, is committed to delivering products that meet the evolving needs of their clients. By offering a range of surface finishes and operating effectively within a wide temperature range, their sling sockets are equipped to handle the demands of both marine and industrial environments. This versatility underscores the importance of Babbitt sling sockets in modern rigging systems.

In summary, sling sockets are essential components in the rigging and lifting industry, offering secure and reliable connections for a variety of applications. As a leading sling socket supplier, Jiangsu Gostern Rigging provides high-quality products that meet the diverse needs of their clients. Their Babbitt alloy sling sockets, known for their strength and corrosion resistance, are adaptable to different industries, ensuring optimal performance in both standard and custom applications. With a commitment to innovation and customer satisfaction, Jiangsu Gostern Rigging continues to set the standard as a top sling socket manufacturer, supporting the expansion of rigging capabilities across the globe.

No comments:

Post a Comment