Table of contents:

Key Benefits of Using Dwellpac Egg Tray Molds in Mass Production

How Custom Molded Pulp Packaging Enhances Efficiency and Sustainability

What Sets a Premium Molded Pulp Packaging Supplier Apart in Today’s Market

Key Benefits of Using Dwellpac Egg Tray Molds in Mass Production

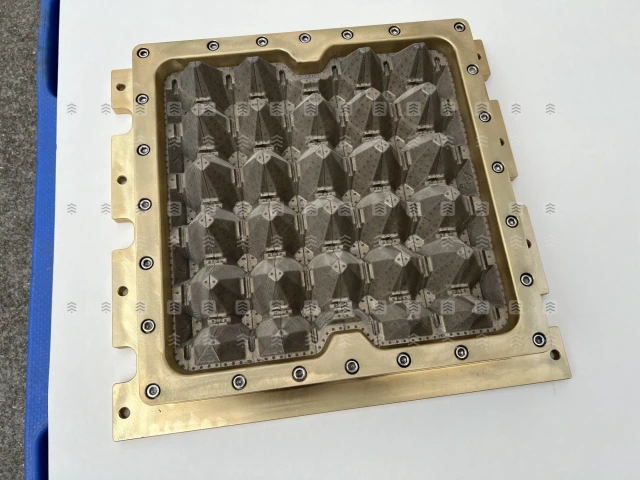

Dwellpac’s molded pulp packaging solutions are renowned for their efficiency and precision. Made from durable aluminum, the egg tray molds ensure consistent product quality, even in high-volume settings. This durability reduces long-term equipment replacement costs, supporting businesses aiming to maximize their return on investment. The molds' biodegradable focus offers an effective way to minimize plastic usage in packaging, aligning perfectly with global sustainability goals. Additionally, their design facilitates fast production cycles, allowing manufacturers to meet increasing demand without sacrificing quality. Customized mold designs ensure that businesses can tailor production to meet their specific requirements, further enhancing efficiency. These molds also perform seamlessly under extreme production conditions, maintaining reliability and ensuring uninterrupted output. With a focus on innovation, Dwellpac equips manufacturers with tools that contribute to both operational excellence and environmental stewardship.

How Custom Molded Pulp Packaging Enhances Efficiency and Sustainability

Custom molded pulp packaging is a game-changer for businesses seeking a balance between environmental responsibility and operational efficiency. Beyond the advantage of being biodegradable, it reduces reliance on plastic, cutting down on waste. Paired with advanced molds like those offered by Dwellpac, manufacturers achieve consistent product quality, which minimizes waste during the production process. This consistency, coupled with Dwellpac’s precision-engineered tools, not only maximizes efficiency but also streamlines operations. By customizing molds to meet specific production needs, businesses save both time and materials, leading to a reduced carbon footprint. This commitment to custom eco-friendly packaging creates an edge for manufacturers in a competitive market where sustainable practices are increasingly valued. Additionally, it enhances brand reputation, as consumers and stakeholders alike increasingly favor companies prioritizing green initiatives. By investing in Dwellpac’s solutions, businesses can seamlessly align profitability with sustainability.

What Sets a Premium Molded Pulp Packaging Supplier Apart in Today’s Market

A premium molded pulp packaging supplier delivers more than just durable equipment. Companies like Dwellpac stand out by offering tailored solutions for their clients, ensuring each production line maximizes efficiency and sustainability. From durable aluminum molds to customizable designs, every product is geared toward meeting both functional and environmental requirements. Suppliers that prioritize innovation, such as by employing cutting-edge engineering and sustainable materials, further distinguish themselves. Additionally, customer support and technical consultation services help businesses integrate these solutions effectively into their operations. When choosing a molded pulp packaging supplier, businesses should look for a partner that aligns sustainability with efficiency and offers flexible solutions like custom eco-friendly packaging. Dwellpac excels in these areas, combining expertise, advanced technology, and a client-focused approach to help molded pulp manufacturers achieve their production goals while adhering to environmental standards and reducing waste.

For businesses seeking premium molded pulp solutions that enhance efficiency and sustainability, Dwellpac’s commitment to innovation, eco-consciousness, and tailored services makes it a standout supplier in the market. With cutting-edge technology, customizable designs, and a focus on reducing environmental impact, Dwellpac ensures your packaging needs are met with precision, reliability, and a greener future in mind.

No comments:

Post a Comment