Table of contents:

Working with Manufacturers to Design Bespoke Optics Benches

Incorporating Specialized Mounts and Holders

Adapting Benches for Cleanroom Environments

Case Studies of Customized Optics Bench Implementations

Working with Manufacturers to Design Bespoke Optics Benches

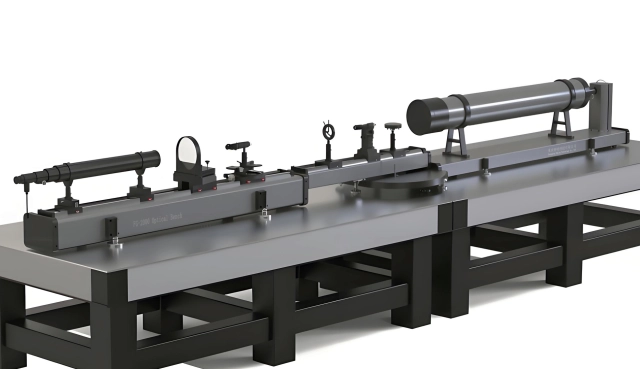

Collaborating with optics bench manufacturers is the ideal approach for creating a bespoke platform that meets specific needs. Manufacturers like Chinacqyl, known for their FG-2000 Optical Bench, provide high-precision systems engineered with durability and versatility in mind. When designing a bespoke bench, the process involves identifying requirements such as dimensions, materials, and modular components for mounting. Manufacturers then produce benches optimized for optical alignment, supporting experiments that involve light transmission or laser systems. Whether your scope demands vibration resistance, increased load capacity, or compatibility with additional components, custom configurations ensure optimal setups that standard models may be unable to accommodate.

Incorporating Specialized Mounts and Holders

One of the most effective ways to enhance an optics bench is by incorporating specialized mounts and component holders. Precision mounts stabilize lenses, mirrors, and other critical parts within the optics system, while fine adjustment mechanisms allow for micro-scale alignments to control optics light paths. V-brackets, objective lens holders, and autocollimation mirrors can easily be integrated into custom optics benches, enhancing the flexibility to accommodate multiple applications. Additional innovations like modular rails or alignment-grade fixtures also support evolving optical system requirements, making your customized bench more versatile and future-proof.

Adapting Benches for Cleanroom Environments

Certain optics applications, especially in fields like semiconductor manufacturing or biomedical imaging, demand adaptations for cleanroom environments. Customized optics benches designed for such purposes feature materials resistant to contaminants, polished surfaces, and finishes that minimize particle adhesion. A cleanroom-compatible optics bench must also balance portability and rigidity, ensuring high alignment accuracy despite stringent environmental restrictions. Effective collaboration with manufacturers in this area involves prioritizing materials, coatings, and assembly processes that meet both cleanliness and functional standards.

Case Studies of Customized Optics Bench Implementations

The benefits of custom optics benches are vividly showcased in real-world applications. For instance, a research lab specializing in laser testing required a bench for controlling beam divergence and analyzing optics light reflections. By co-developing a modular bench equipped with mounted collimators and neutral density filters, the lab improved its setup accuracy by 30%, enabling more precise data collection. Similarly, a cleanroom-class bench allowed an R&D facility working on optics systems for telecommunications to scale their experiments, accommodating enhanced lens-mount designs for testing multiple parallel configurations. These examples underline how tailored solutions transform operational efficiency while boosting research and development capabilities.

Customization is the key to unlocking the full potential of optics benches across industries and research fields. Whether through tailored dimensions, precision mounts, or cleanroom-ready designs, working closely with an experienced optics bench manufacturer ensures that your bench meets specific application needs. With leading manufacturers like Chinacqyl offering advanced customization for benches like the FG-2000 Optical Bench, investing in tailored solutions translates into unmatched precision, flexibility, and long-term value.

No comments:

Post a Comment