In today's demanding electronic landscape, effective thermal management is paramount. As devices shrink and power densities increase, the need for reliable and efficient heat dissipation solutions becomes ever more critical. This is where the expertise of a specialized heat sink manufacturer comes into play. This article explores the intricacies of optimizing thermal performance with a specific focus on 30mm x 25mm heatsinks, highlighting design considerations, customization options, and the importance of rigorous testing. We'll delve into how these compact yet powerful solutions can safeguard your critical electronic components and ensure long-term operational stability.

Table of contents:

Technical Specifications of 30mm Width x 25mm Height Heatsinks

Customization Options for Compact Heatsink Dimensions

Thermal Performance Testing Methods for Standard-Sized Heatsinks

Technical Specifications of 30mm Width x 25mm Height Heatsinks

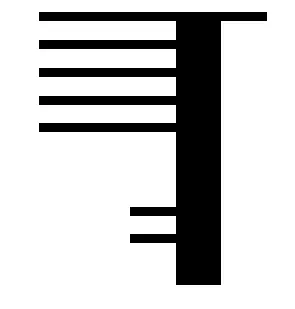

The 30mm x 25mm heatsink presents a balanced approach to thermal management in space-constrained applications. These heat sinks, often crafted using aluminum extrusion, provide a substantial surface area for heat dissipation while maintaining a compact footprint. According to information readily available from leading suppliers like Renxin Precision, such as their Extruded Profiles Heatsink offerings found on pages like https://www.renxin-precision.com/products/width30mm-x-height25mm-heatsink-225, these models typically feature precisely engineered fin structures to maximize airflow and heat transfer efficiency. Key specifications to consider include fin density, material thermal conductivity, and the overall thermal resistance (measured in °C/W). Choosing the right specifications is crucial for achieving optimal cooling performance for your specific application, preventing overheating and potential component failure.

Customization Options for Compact Heatsink Dimensions

While standard 30mm x 25mm heatsinks offer a readily available solution, customization is often necessary to meet specific application requirements. A competent heat sink manufacturer will offer various customization options, including altering fin height and spacing, adding mounting features, and applying surface treatments to enhance thermal conductivity or corrosion resistance. For instance, anodizing can improve radiative heat transfer, while chromate conversion coatings can provide corrosion protection. Furthermore, the choice of attachment method – be it thermal adhesive, clips, or screws – can significantly impact thermal performance and ease of installation. Tailoring these aspects ensures a perfect fit and optimal heat dissipation for your unique device.

Thermal Performance Testing Methods for Standard-Sized Heatsinks

Rigorous testing is essential to validate the effectiveness of any heatsink design. Standard testing methods include Computational Fluid Dynamics (CFD) simulations to predict thermal performance, and physical testing under controlled conditions to verify these simulations. Common physical testing methods involve mounting the heatsink onto a simulated heat source and measuring its temperature under varying power loads and ambient temperatures. Thermal resistance is a key metric derived from these tests, indicating the heatsink's ability to dissipate heat. By comparing the performance of different designs and materials under identical testing conditions, engineers can accurately assess their suitability for specific applications and make informed decisions about thermal management strategies. Choosing a heat sink manufacturer that prioritizes comprehensive testing ensures that you are receiving a product that meets the promised performance specifications.

In conclusion, selecting the right 30mm x 25mm heatsink involves careful consideration of technical specifications, customization options, and rigorous performance testing. Engaging with an experienced heat sink manufacturer like Renxin Precision allows you to leverage their expertise in Extruded Profiles Heatsink design and optimization, ensuring your electronic devices operate reliably and efficiently. By prioritizing thermal management, you can significantly improve the lifespan and performance of your critical electronic components. Don't underestimate the importance of proper heat dissipation – it's an investment in the longevity and reliability of your technology. Explore the customization options available and demand comprehensive testing data to make an informed decision and safeguard your electronics from the detrimental effects of overheating.

No comments:

Post a Comment